Schulte Starclean Conveyor Belt Cleaner

- Mar 1, 2024

- 3 min read

Updated: Apr 29, 2024

ADVANTAGES AT A GLANCE

Perfect, belt-saving cleaning

Extremely long lifespan thanks to low wear

Tool-less scraper blade replacement

Quick and easy mounting and maintenance

Optimum adjustment to the conveyor belt thanks to TWIST-SWING®

Unique, modular system

Top-quality materials: high-performance polyurethane or polyurethane base with special tungsten carbide blades

TWIST - SWING

Optimum adjustment of each scraper blade to the belt surface

Ability to evade obstacles

Flawless cleaning results

For any belt width, belt speed or bulk material:

WE HAVE THE RIGHT SOLUTION!

PRIMARY SCRAPERS

SERIES 700

WITH TORISON - TENSIONING DEVICE

WITH TUNGSTEN CARBIDE

SCRAPER BLADES

Available types:

85, 285, 86 and 286

Suitable for reversible operation

WITH POLYURETHANE

SCRAPER BLADES

Available types:

18, 81, 82, 281, 282 and 283

Suitable for reversible operation

and mechanical belt joints

SERIES 700 FOR HEAVY-DUTY BELT CONVEYORS

WITH TORSION-TENSIONING DEVICE

WITH TUNGSTEN CARBIDE

SCRAPER BLADES

Available types: 385

Suitable for reversible operation

WITH POLYURETHANE

SCRAPER BLADES

Available types:

481, 481-HD, 581, 681 and 781

Suitable for reversible operation

and mechanical belt joints

SERIES 800

WITH RASTER-TENSIONING DEVICE

WITH TUNGSTEN CARBIDE

SCRAPER BLADES

Available types: 85, 285, 86 and 286

Suitable for reversible operation

Overlapping cleaning with types 85 and 285

SERIES 600 FOR HEAVY-DUTY BELT CONVEYORS

WITH LEVER-TYPE TENSIONING DEVICE

WITH TUNGSTEN CARBIDE

SCRAPER BLADES

Available types: 385

Fable for reversible operation

WITH POLYURETHANE

SCRAPER BLADES

Available types:

481, 481-HD, 581, 681 and 781

Suitable for reversible operation

and mechanical belt joints

SECONDARY SCRAPERS

SERIES 800

WITH RASTER - TENSIONING DEVICE

WITH TUNGSTEN CARBIDE

SCRAPER BLADES

Available types: 08, 09, 50, 53, 54, 56 and 256

Overlapping cleaning with types 50, 53, 56 and 256

Suitable for reversible operations type 09

Suitable for mechanical belt joints type 50 and 54

SERIES 800 FOR HEAVY-DUTY BELT CONVEYORS

WITH RASTER-TENSIONING DEVICE

WITH TUNGSTEN CARBIDE

SCRAPER BLADES

Available types: 66 and 266

Overlapping cleaning

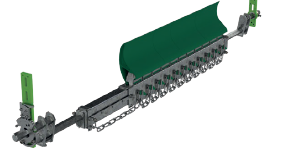

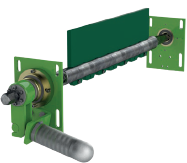

SERIES 500

WITH SEGMENTED PRESSURE ROLLER SYSTEM

WITH TUNGSTEN CARBIDE BLADE

Available types: 08 and 09

Suitable for reversible operations

For particularly abrasive, sticky materials

With single-piece or two-piece tensioning device

Belt-saving operation due to deflecting segmented rollers

Optimum pressure of the belt against the carbide blade

Version for heavy-duty belt conveyors also available

SCRAPER

NEXT-GENERATION SCRAPERS

SERIES 830-E

WITH AUTOMATIC TENSIONING DEVICE

Suitable for reversible operation

Interval-based or load-based cleaning possible

Electric linear drive unit (retrofitting possible)

WITH POLYURETHANE

SCRAPER BLADES

Available types: 18, 81, 82, 281, 282 and 283

For primary scrapers

WITH TUNGSTEN

CARBIDE SCRAPER BLADES

Available types: 50, 53, 54, 56, 256, 08 and 09

For secondary scrapers

SERIES 860-RS

WITH RASTER-TENSIONING DEVICE

Easy and quick maintenance outside of the transfer chute

Convenient removal of each scraper blade from the side

Reliable and safe scraper blade replacement without reaching into the system

WITH TUNGSTEN CARBIDE

SCRAPER BLADES

Available types: 85, 285, 86 and 286

For primary scrapers

WITH TUNGSTEN

CARBIDE SCRAPER BLADES

Available types: 50, 53, 54, 56 and 256

For secondary scrapers

WITH POLYURETHANE

SCRAPER BLADES

Available types: 18, 81, 82, 281, 282 and 283

For primary scrapers

SPECIAL

SOLUTIONS

SERIES 400

FOR CHEVRON CONVEYORS

WITH POLYURETHANE BLADE

Available types: 04 and 07

Slotted or continuous

For use on the return side of the belt

BRUSH CLEANER

WITH BEATING DRUM

WITH FIXED BRUSH

Poly bristles

For use on the return side of the belt

Alternatively with polyurethane blade